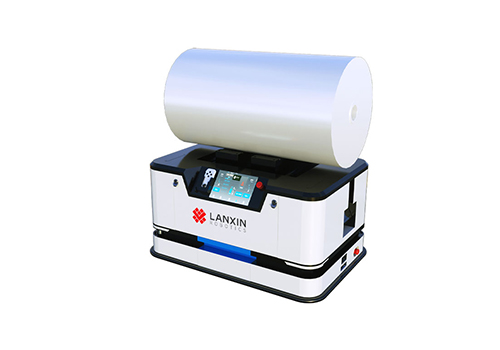

VMR-FR3300L

On June 13th, the 17th International Solar Photovoltaic and Smart Energy (Shanghai) Conference (2024 SNEC) opened grandly at the National Exhibition and Convention Center in Shanghai. Lanxin made a notable appearance by showcasing its comprehensive smart logistics solutions tailored for the photovoltaic (PV) industry, drawing significant attention from industry professionals and media alike. Lanxin’s solutions cover key production processes, including crystal pulling, solar cell manufacturing, and module assembly, providing a holistic approach to smart logistics in solar energy production.

1

Monocrystalline Production

Smart Logistics Solutions

Automatic Silicon Material Transport: Robots autonomously transport silicon materials to the crystal pulling furnace, minimizing manual handling and boosting production efficiency.

Unmanned Crystal Rod Transfer: Robots replace manual labor in transferring long crystal rods, ensuring their safety during transit.

Automated Material Transport for Subsequent Processes: Robots autonomously transfer materials during subsequent processes such as cutting, squaring, and grinding of crystal rods, reducing the workload of manual transport.

Automated Waste Handling: Robots facilitate automated waste processing, improving resource utilization efficiency.

Lanxin’s AGVs and crystal rod transport robots are equipped with the LX-MRDVS® core technology, featuring 3D vision obstacle avoidance and semantic recognition capabilities. This allows for 360° panoramic obstacle detection, enhancing safety and making obstacle avoidance smarter.

2

Solar Cell Production

Smart Logistics Solutions

Enhanced Production Efficiency: Automation of material transport from feed-in to offline, and between various production processes, reduces manual intervention and improves product yield.

Reduced Labor Costs: Automated material handling reduces reliance on manual labor, lowers labor intensity, and decreases staff turnover, thus reducing management costs for enterprises.

Intelligent Management: The photovoltaic Manufacturing Control System (MCS) integrates upper-level software, robot clusters, and production equipment, enabling coordinated planning and intelligent scheduling across diverse devices.

Adaptation to Diverse Production Needs: The use of industry-leading 3D vision navigation technology allows the system to adapt to complex production environments and processes, with customized hardware development to meet the intricate demands of factory production.

Facilitating Industry Upgrade: The application of robots and related solutions helps photovoltaic companies transition from "manufacturing" to "intelligent manufacturing," enhancing their competitiveness in the market.

Lanxin’s integrated basket loading and unloading robots can handle 20 solar cell baskets at once. Equipped with Lanxin’s LX-MRDVS® core technology, these robots provide stable positioning and safer operation through 3D vision navigation and obstacle avoidance.

3

Module Production

Smart Logistics Solutions

Glass Sheet Loading: Transporting glass sheets to designated positions for subsequent processing.

EVA Film Cutting and Placement: Transporting EVA films to the cutting area, ensuring that the films are cut and shaped to meet specifications.

Automatic Template Loading: Transporting templates to the corresponding workstation for module assembly.

Automatic String Welding: Transporting solar cells to the string welder for series welding.

Back Glass Placement: Transporting back glass to the module for encapsulation.

EL Testing Unit: Transporting modules to the EL testing area to check the performance of solar cells.

Automatic Packaging: Transporting modules to the packaging area for final packing.

Automated Storage and Retrieval: Transporting finished modules to the warehouse or retrieving them from the warehouse for shipment.

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry